45 Years of Supporting Artists

Our Campus.

Your Studio.

Discover 100,000 square feet of cutting-edge technology and equipment at our Walla Walla campus. Designed with artists in mind, our facility supports the way you work — offering a destination studio that fosters creativity, collaboration, and experimentation.

Explore materials and processes alongside our experienced team, who are here to help push the boundaries of what’s possible while keeping your artistic vision at the center of it all.

Capabilities

Design and Consulting Services

Project Management & Consulting

Digital Modeling & Point Up

3D Scanning

Photography

Production Abilities

3D Printing

Mold Making

Pattern Making

Metal Casting

Resin Casting

CNC Machining

Waterjet Cutting

Custom Product Development

Custom Fabrication

Furniture Design & Fabrication

Architectural Design & Collaboration

Mixed Media Artworks

Post-Processing and Finishing

Stainless Steel Polishing

Patination

Custom Painting & Detailing

Photography & Video

Logistics and Installation

Crating

Logistics & Shipping

Installation Services

Extensive Installation Manuals

Conservation and Restoration

Sculpture Conservation

Restoration

Condition Reports

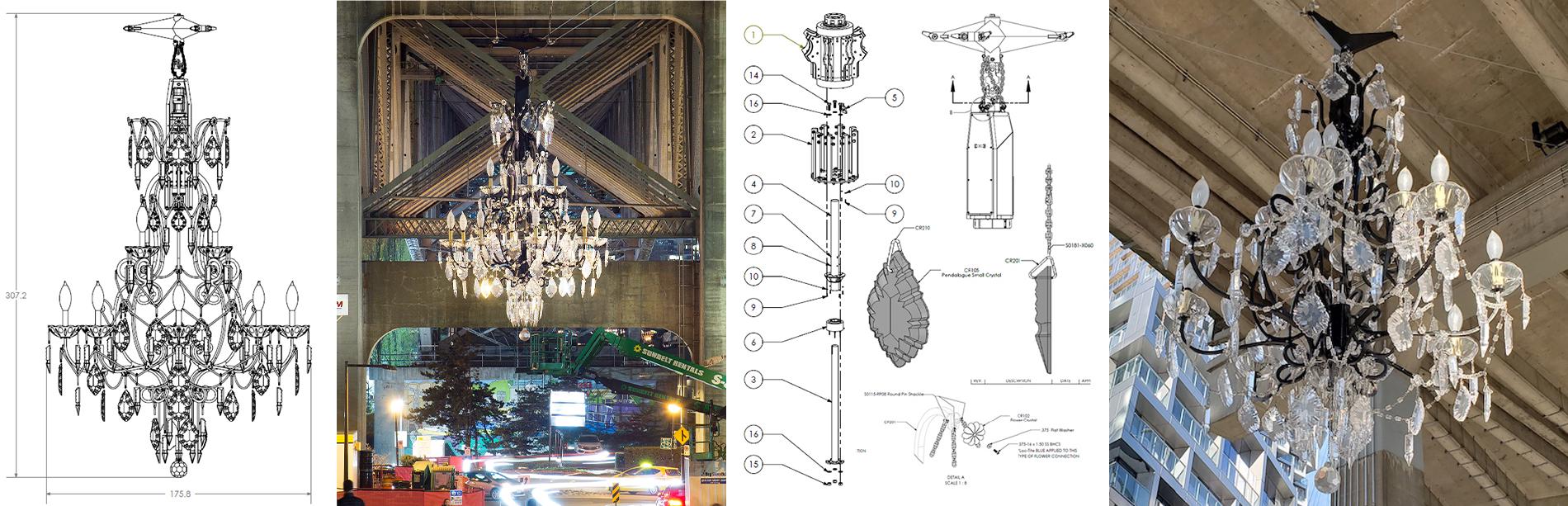

From Sketch to Installation

Every project is unique. Our team brings a refined process and deep expertise to each stage of fabrication — ensuring your artistic vision is realized from initial concept to final installation.

Comprehensive Fabrication Under One Roof

All capabilities in-house—from concept to installation.

One Point of Contact

A dedicated project manager guiding every step.

Built for Real-World Installation

We plan with the end in mind from day one.

Clarity Through Every Phase

Track progress with regular updates and photos.

Creative Problem-Solving

No challenge is too complex—innovation is our default.

Guiding Your Installation Step by Step

Detailed manuals ensure smooth, successful installs.

Capacity & Technologies

Large-Envelope 3D Printing, PMMA

We operate two cutting-edge Voxeljet 1000 printers (build envelope: 39.3” × 23.6” × 19.6”), allowing us to prepare digital files and 3D print precision patterns for casting at impressive scale.

Bronze Pouring Capacity

We pour bronze at capacities ranging from 400 to 1,800 lbs. per session — enabling us to handle projects of exceptional size and complexity.

Stainless Steel Welding

Certified AWS D1.6, 6G structural stainless steel fabricators, ready to deliver precise, high-performance welds for even the most demanding projects.

Paint Booth

Our custom-built 40’ × 18’ × 15’ modified downdraft booth, complete with a connected mixing room, provides an ideal environment for delivering flawless, high-quality paint finishes. Fully compliant with all local, state, and federal safety regulations.

Patina Expertise

We bring a deep understanding of both traditional patinas and innovative contemporary finishes, helping realize an artist’s vision with exceptional surface treatments.

Diverse Material Capabilities

Wax, steel, wood, rubber, cork, acrylic, glass, basalt, resin, stainless steel, bronze, aluminum, brass, copper, silver — and we’re always excited to collaborate with artists to explore unique materials in bold new ways.

No Project Too Big – Or Too Small

Our Safety Policies

Our proactive safety culture has earned us one of the lowest injury rates in the industry—driven by leading indicators, engaged employees, and strong leadership. In a recent review, L&I officials praised our comprehensive safety programs and the exemplary behavior of our team.

Thanks to focused improvement efforts in key areas, we achieved an initial 85% reduction in employee injuries. For the past three years, our total recordable incident rate has remained well below the industry average.

Trained to Stay Safe

Ongoing education keeps our team up to date on evolving safety protocols.

PPE is Non-Negotiable

We provide and strictly enforce the right gear for every task.

Hazards, Monitored and Managed

Routine exposure testing ensures risks are identified early.

Safety Starts with Us

Active employee-led committee drives a culture of accountability.

Smart by Design

Engineering controls reduce risk before it reaches the floor.

Safety is Everyone’s Job

We empower employees to protect themselves and each other.

Our Environmental Practices

We’ve achieved a 90% reduction in hazardous waste over the past two years by rigorously evaluating our waste streams and implementing innovative recycling, reuse, reduction, and replacement strategies. These environmental and safety practices not only ensure a healthy, secure workplace for our employees but also advance our commitment to a sustainable future.

Environmentally Friendly Fluids

We replaced the cutting fluids used in our band saws, lathe, and mill with eco-friendly alternatives that can be recycled, significantly reducing waste.

Solvent Distillation

We now distill and reuse paint solvents, reducing this waste stream by approximately 99%.

Air Emissions

Our air emissions remain below EPA modeling thresholds. Still, we continuously seek ways to further reduce them, reflecting our commitment to environmental stewardship and ongoing improvement.

Solar Energy

Our solar system, with 222 high-efficiency panels, generates up to 200 kW of clean energy annually—enough to power 40 average American homes. Designed for peak performance, it has significantly reduced our dependence on traditional energy sources.

DOE Demonstrations

Extensive testing confirmed to the Department of Energy (DOE) that our primary waste streams are environmentally safe, allowing us to transition from a “Large Quantity Generator” to a “Small Quantity Generator” status.